gas pressure welding cataloge

Gas Pressure Welding Catalog- KENZA WELD

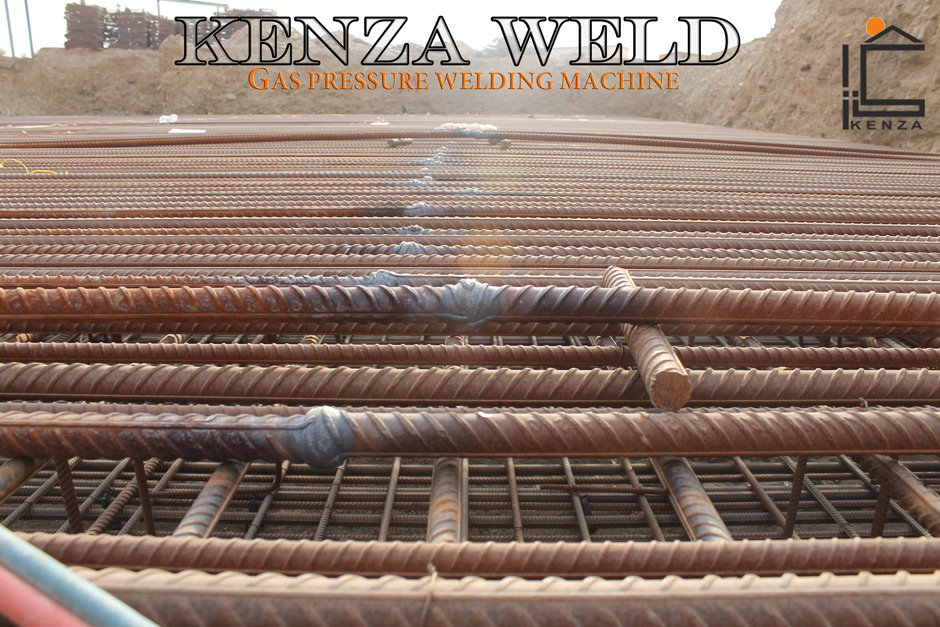

Gas pressure welding of rebar process

Gas pressure welding of rebar is one of the methods in oxy acetylene welding in which the rebars reach getting-pastytemperature (1,200-1,300 degrees centigrade),without melting the base metaland any additives, tip-to-tip by the heat resulting from oxyacetylene flame and get connected to each other by the pressure resulted from hydraulic cylinder)RAM)

Molecules of two welded surfaces transfer to each other without any changes in structure and mechanical properties. Reinforce bar is steel witch is mixed by atom of iron and carbon

Atom of them in steel stable at normal temperature and they are making regular arrangement

Gas pressure welding stick each reinforce bar by their join of crystal

Then we used heat to make rearrangement of each atom easily at each reinforce bar joining

Both atom start to move actively by heating at once and also change structure crystal as before then diffuse. It means they start to be mixed of each atom

Why Gas pressure welding of rebar?

A lack of enough stabilityat the location of connection and increased density in some areas caused some traditional method of rebars’ overlapping to be replaced by (coupler) mechanical connections method and this method was not welcomed due to making delay in project advancement scheduling (due to time-consuming preparation and execution as well as high costs) at the onset and was not limited to be used in special projects

Gas pressure welding is a very proper method and good replacement instead of overlap traditional method and mechanical connections method as the latest method in buildings components with an easier, faster, cheaper and higher stability

Gas pressure welding can save your cost and quantity of reinforce bar at your site definitely

Advantages of gas pressure welding

Increased resistance in connection point due to increased diameter

30% save in rebar consumption

Reduced human errors in rebar binding and layout of rebar

Weight reduction in structure due to overlap elimination

Increase in structure resistance against external forces (earthquake etc.) due to weight reduction in structure and a reduction in gravity force

Increase in concrete mix with rebar due to a decrease in rebar dimensions

The possibility to a better and more ideal vibration due to a decrease in volume of reinforcements

A reduction in areas and consumption of concrete and a reduction of dead space under the building (in pillars)

Maintenance of integration of bar’s certificate of analysis in connection point

A reduction in transportation costs due to a reduction in consumable materials

Ability to create a connection with at least 10 cm reinforcement length

Preservation of rods’ metallurgical properties

The possibility to connect different sizes (according to standard) to each other

High execution pace with the least expense and time-waste prevention of reinforcing executive personnel

The possibility to connect scrap rebars

Usability in all circumstances including columns, shear walls, beams, foundation etc

Lack of need to high-voltage electricity

Comfortable application and portable by human

پیوستها:

| فایل | توضیحات | تاریخ | اندازه |

| gas pressure welding cataloge | ۱۴۰۱/۱۲/۲۸ | 4.1 مگابایت |

نظرات:

پیشنهاد میکنم

کاتالوگ دستگاه فورجینگ به زبان فارسی هم موجود هست؟ 305 300

پیشنهاد میکنم

بله.کاتالوگ دستگاه فورجینگ به زبان فارسی ازقسمت دانلودها قابل دریافت می باشد. 284 275